Trenching, or what is trenching, refers to the process of digging long, narrow holes in the ground. This technique is crucial for establishing pathways for water, gas, and power lines.

The practice of trenching is widely utilized and is experiencing a growing demand. The market for trenching is projected to expand from $3.2 billion in 2023 to $5.1 billion by 2032, highlighting its significance in modern construction projects.

However, safety remains a major concern; between 2013 and 2017, approximately 19 individuals lost their lives each year due to trenching accidents. Therefore, careful planning is essential to enhance the safety and effectiveness of trenching operations.

The FJD G31 Pro 3D Excavator Guidance System is specifically designed to enhance trenching accuracy and efficiency. This cutting-edge system provides real-time 3D guidance, allowing operators to dig with centimeter-level precision—eliminating the need for manual staking and reducing rework. Whether you’re installing pipelines, cables, or drainage systems, the G31 Pro ensures consistent trench depth and slope, improving job site productivity while minimizing fuel and labor costs.

Take trenching to the next level with the FJD G31 Pro. Get a quote today and dig smarter!

What is Trenching and Its Purpose

What is Trenching?

Trenching means digging long, narrow holes in the ground. These holes are used to place underground utilities like water, gas, and power lines. Workers use tools or machines to remove soil and prepare the area. This process is important for construction projects to install pipelines and other key systems.

But trenching can be dangerous. OSHA warns that unprotected trenches may collapse or cause falls. To avoid accidents, safety plans and protective systems are necessary. Groups like the National Utility Contractor Association work to teach people about these risks.

Purpose of Trenching in Construction

The main goal of trenching is to install and fix underground utilities. It creates safe paths for pipes, cables, and conduits. Trenching also helps make strong foundations for buildings. It manages water flow through drainage systems, stopping floods and erosion.

Aspect | Details |

|---|---|

Definition | Trenching means digging narrow holes for underground utilities. |

Safety Concerns | Risks include cave-ins and falls, as noted by OSHA. |

Purpose | Used to install and maintain pipes, cables, and conduits in construction. |

Common Applications of Trenching

Utility Installation (e.g., water, gas, and electrical lines)

Trenching is often used to install underground utilities. It helps place water, gas, and power lines safely. Special machines dig carefully to avoid damaging the surface. Trenches must be the right size for safe pipeline installation.

Foundation and Structural Support

Trenches give buildings a strong base. They spread the weight evenly to stop shifting or sinking. These trenches are key to keeping buildings strong over time.

Drainage and Irrigation Systems

Drainage trenches control water to stop flooding and erosion. They are also used in irrigation to guide water to crops. By managing water, trenches protect land and help farming.

💡 Tip: Before trenching, check the soil type and depth needed for safety and success.

How Trenching is Done

Tools and Equipment for Trenching

Manual tools (e.g., shovels, picks)

For small jobs, manual tools like shovels and picks work well. These tools are best for shallow trenches or tight spaces. They allow careful digging and cost less for small projects. But using them takes more time and hard work.

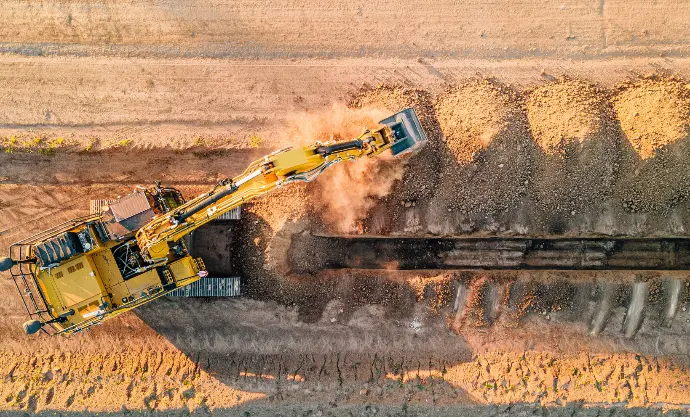

Heavy machinery (e.g., trenchers, excavators)

For bigger or deeper trenches, machines like trenchers and excavators are needed. Trenchers cut narrow, deep trenches, perfect for utility work. Excavators can do many trenching tasks and save time. These machines need skilled operators to work safely and efficiently.

Steps in the Trenching Process

Site preparation and planning

Before digging, plan the layout of the job. Choose safe spots for soil piles and machine paths. Call 811 to mark underground utilities and avoid damage. Check soil stability with simple tests like pressing your thumb into it. Good planning makes trenching safer and easier.

Excavation and soil removal

After planning, start digging with the right tools or machines. Remove soil carefully and place it in safe piles. Keep trench walls stable to stop collapses during this step.

Safety measures during trenching

Safety is very important in trenching. From 2019 to 2021, 38 workers died in trench collapses. Teach workers about dangers and safe methods. Use trench boxes or shoring to keep walls stable. Workers under 18 should never enter a trench. Always have an emergency plan ready.

Types of Trenches

Open trenches

Open trenches are the most common type. They are wide and shallow, good for utilities and drainage. These trenches are easy to work in but may disturb nearby areas.

Narrow trenches

Narrow trenches are used in tight spaces. They are great for small pipes or cables. These trenches cause less surface damage but need careful digging.

Deep trenches

Deep trenches are used for building foundations or big pipelines. These trenches are risky and need safety systems to prevent cave-ins. Follow strict safety rules when working on deep trenches.

💡 Note: Always check the soil type and depth before picking tools or trench types.

Advantages and Disadvantages of Trenching

Advantages of Trenching

Cost-effectiveness for certain projects

Trenching is a cheaper option for many projects. The tools and machines needed are not very expensive. This makes it a good choice for saving money. Also, these tools are easy to find, which saves time. In rural areas, trenching is both useful and affordable.

Accessibility for repairs and maintenance

Trenching makes underground utilities easy to reach. This helps with quick repairs and checks. Fixing or adjusting utilities becomes simple and fast. For projects needing regular maintenance, trenching works well.

Simplicity in execution

Trenching is simple to do and easy to learn. Workers can quickly start using trenching tools. This lowers labor costs and speeds up projects. Its ease makes it popular for jobs needing exact depth control.

Disadvantages of Trenching

Environmental impact and surface disruption

Trenching can harm the environment. Digging may cause soil erosion and destroy habitats. It also creates waste, like leftover pipe materials. Wetlands and other sensitive areas are at high risk. Fixing these areas after trenching takes time and effort.

Safety risks (e.g., cave-ins, worker injuries)

Trenching can be dangerous for workers. From 2013 to 2017, about 19 workers died each year in trenching accidents. Cave-ins are the biggest danger and can cause serious injuries. Using safety tools like trench boxes is very important to keep workers safe.

Time-consuming for large-scale projects

Big trenching projects take a lot of time. Hard soil, bad weather, or tricky land can slow work. These delays make projects longer and cost more. Workers earn $35 to $65 per hour, so delays increase expenses.

Disadvantage | Description |

|---|---|

Environmental disruption | Causes soil erosion, habitat destruction, and waste generation. |

Safety risks | Includes cave-ins and worker injuries, with 97 fatalities reported from 2013-2017. |

Time-consuming | Influenced by terrain, weather, and project complexity, leading to extended timelines. |

Alternatives to Trenching

Semi-Trenchless Methods

Description and applications

Semi-trenchless methods mix trenching with new technology to reduce surface damage. These methods work well for pipelines near the ground.

For example, the Pipe Express method uses small machines and boring tools to install pipes. This method cuts ground space use by up to 70% compared to open trenching. Semi-trenchless methods are also controlled remotely, making them safer and more accurate.

Cured-in-Place Pipe (CIPP) renewal is another semi-trenchless option. It is often used to fix underground sewer pipes. Research shows CIPP can lower costs by 57% to 63% for small and medium pipes. This makes it a budget-friendly choice for cities upgrading old systems.

Benefits over traditional trenching

Semi-trenchless methods have many benefits over regular trenching. They need less digging, which means less surface damage and cheaper repairs. These methods also improve safety by keeping workers out of dangerous trenches. They save time and resources, making them great for both city and rural projects.

Trenchless Techniques

Horizontal directional drilling (HDD)

Horizontal directional drilling (HDD) installs pipes and cables without big trenches. It starts with a small hole that is widened for the pipe. HDD is perfect for crossing rivers, roads, or train tracks. It causes less harm to the environment and reduces repair needs.

Pipe bursting

Pipe bursting replaces old or broken pipes by breaking them and adding new ones. This method upgrades systems without disturbing the area around them. It also helps the environment by cutting waste and protecting nature.

Comparing Trenching and Alternatives

Cost differences

Trenchless methods cost more upfront, about $80 to $250 per foot. Traditional trenching costs $50 to $250 per foot. But trenchless methods save money later by cutting labor and repair costs. Over time, they can save up to 79%.

Environmental impact

Trenchless methods lower greenhouse gas emissions and create less waste. They protect ecosystems and reduce noise and visual pollution. These features make trenchless methods more eco-friendly than trenching.

Suitability for different project types

Trenching works best for shallow projects or when saving money matters most. Trenchless methods are better for sensitive areas or tough landscapes. They are also ideal for cities where reducing disruption is important.

🌍 Note: Trenchless methods support eco-friendly goals, making them great for modern projects.

Trenching is important in construction for placing underground utilities. It also helps build strong foundations and controls water flow. It is affordable and makes repairs easier but has dangers. These include harming the environment and causing worker injuries.

In 2022, deaths from trenching rose by 160%. Construction workers made up 85% of these deaths in the last 10 years. Safer and greener options, like trenchless methods, are available. However, they can cost more at first. Picking the best method depends on project needs, safety, and the environment.

FAQ

What is the safest way to perform trenching?

Always use safety tools like trench boxes to stop cave-ins. Train workers on safety rules and check the site often. Never go into trenches over 5 feet deep without safety steps.

How do you choose the right trenching equipment?

Pick tools based on trench size and soil type. Use hand tools for small or shallow trenches. For bigger jobs, machines like trenchers or excavators are better. Think about the project’s needs and budget.

Can trenching harm the environment?

Yes, trenching can hurt nature, cause soil loss, and make waste. Plan well and fix the area after the job to reduce damage. Trenchless methods are better for fragile environments.

What are trenchless methods, and when should you use them?

Trenchless methods fix or install utilities without much digging. Use them in cities, under roads, or near rivers to avoid surface damage. They are great for projects needing less disruption.

How do you prevent delays in trenching projects?

Plan carefully before starting. Check the weather, soil, and underground utilities. Use the right tools and train workers to avoid errors. Regular checks help keep the project on track.