Construction site safety is very important in 2025. The industry causes 1 in 5 deadly injuries in the U.S. New rules and better technology have improved safety but need care. In 2024, 26% of deadly injuries happened in construction. Following safety rules saves lives, stops accidents, and helps projects succeed. Keeping the site clean and safe is not optional—it’s your duty.

Boosting Construction Site Safety with Smart Machine Control

Safety on construction sites is non-negotiable—and FJDynamics’ advanced systems help make operations safer and more controlled. From the G31 Pro 3D Excavator Guidance System to the H36 Pro 3D Motor Grader Control System and H39 Pro 3D Dozer Control System, these technologies minimize human error and reduce on-site risks. Real-time positioning, automated grading, and precise excavation help operators avoid utility strikes, over-digging, and accidental intrusions—especially in high-risk or congested zones. With fewer workers needed near machinery, and more accurate control from the cab, site safety is drastically improved.

Want safer, smarter job sites? Request a quote now and explore how FJD tech protects your team and your timeline.

1. Keep Construction Sites Safe with PPE

PPE is very important for staying safe on construction sites. It protects you from dangers and lowers the chance of getting hurt. Wearing the right gear helps you work safely and focus on your tasks.

Must-Have PPE for Construction Workers

Construction workers need certain gear to stay protected. Important items include:

Hard hats: Keep your head safe from falling objects and hits.

Safety glasses or goggles: Protect your eyes from dust, debris, and chemicals.

High-visibility vests: Help others see you on busy sites.

Gloves: Shield your hands from cuts, burns, and chemicals.

Steel-toed boots: Keep your feet safe from heavy or sharp objects.

Hearing protection: Protect your ears from loud noises.

Respirators: Stop harmful dust or fumes from entering your lungs.

Wearing gear that fits well is very important. Loose or oversized gear can cause accidents. For example, big gloves might get stuck in machines, and loose vests can make you trip. Always check that your gear fits properly and meets safety rules.

How PPE Helps Prevent Injuries

PPE helps lower the chance of getting hurt on the job. Studies show using PPE can reduce injuries and deaths by 35%. For example, hard hats stop head injuries, and respirators protect your lungs from dust and chemicals. The injury rate of 2.6 per worker shows why wearing PPE matters.

Learning how to use PPE makes it work better. Workers who know how to wear and care for their gear are safer. By using PPE correctly and following safety rules, you can make the site safer for everyone.

2. Build a Safety-First Mindset with Training

Why Regular Safety Training Matters

Safety training helps lower injuries and accidents on construction sites. When workers know safety rules, they can spot dangers and avoid them. Companies that focus on training see big safety improvements.

Evidence | Effect on Accidents |

|---|---|

Strong safety training programs | |

Regular training sessions | 50% drop in accidents over three years |

New training program in place | 40% fewer accidents in one year |

Monthly safety workshops | Accident rate fell from 1.7 to 0.5 per 100 workers |

Training not only cuts accidents but also builds a safety-first culture. Workers feel safer when they know how to handle risks. This confidence improves teamwork and reduces mistakes.

Tip: Hold monthly safety workshops to teach the latest safety tips.

Important Safety Training Topics

Good safety training focuses on key areas for construction safety. Training should include:

Fall protection: Show how to use harnesses and rescue tools.

Tool use: Teach safe ways to handle and care for tools.

Spotting hazards: Train workers to notice risks like loose scaffolding or wires.

Emergency plans: Prepare workers for accidents or bad weather.

Statistics show why these topics matter. Over 60% of accidents happen in a worker’s first year, often due to poor training. Workers trained in fall safety are eight times more likely to use gear, cutting deadly falls by 76%.

Spending on safety training saves money too. OSHA says companies save $4 to $6 for every $1 spent on training. By teaching key topics, you can create a safer workplace and better project results.

Note: Use toolbox talks to remind workers about safety on-site.

3. Keep Construction Safe with a Tidy Worksite

Dangers of Messy Work Areas

A messy worksite can be dangerous for everyone. Disorganized spaces make trips and falls more likely. Workers might trip on cords, slip on wet spots, or stumble over scattered tools. These accidents can cause serious injuries, delay work, and raise costs.

Leftover materials like sawdust can also be harmful. Breathing in sawdust can hurt your lungs. Sharp objects left out can cause cuts or injuries. Messy areas also make moving equipment harder, which can lead to crashes or damage.

Easy Ways to Keep the Site Clean

Keeping a worksite clean doesn’t have to be hard. Simple cleaning habits can stop injuries and keep projects running smoothly. Try these tips:

Clear unused tools and supplies quickly: Don’t let things pile up. Remove items you’re not using to keep paths clear.

Clean up debris often: Sweep sawdust and throw away trash to avoid slips and breathing problems.

Tidy cords and cables: Cover or secure them to walls to prevent tripping.

Set storage spots: Have specific places for tools and materials. This keeps things organized and easy to find.

Check the site daily: Walk around at the start and end of the day to spot and fix hazards.

By following these tips, you can make the worksite safer and more organized. A clean site reduces accidents and keeps projects on time.

4. Ensure Proper Use of Tools and Equipment

Why Tool Care and Checks Matter

Taking care of tools keeps everyone safe on the job. Fixing and cleaning tools often makes them work better and avoids accidents. Broken tools can fail suddenly and hurt people. For example, a saw with a dull blade might slip and cause injuries.

Always check tools before using them. Look for cracks, rust, or loose parts. If something is wrong, fix or replace the tool right away. Using damaged tools can slow work and cause accidents.

How to Use Tools Safely

Using tools the right way is very important. Always follow the instructions and use tools for their real purpose. Misusing tools can break them and cause injuries. For example, using a wrench as a hammer can hurt your hand and damage the wrench.

Keep your workspace neat to avoid accidents. Put tools you’re not using in their proper places. This stops clutter and helps you find tools faster. By following these tips, you can work safely and get more done.

5. Implement Fall Protection Measures

Common Fall Hazards and Their Impact

Falls are one of the biggest dangers on construction sites. Working high up, open edges, and wrong ladder use cause many accidents. These problems often lead to bad injuries or even deaths. In 2023, falls caused 39% of deaths in construction. Of these, 42% happened because workers didn’t have a personal fall arrest system (PFAS).

Fact: Falls from heights made up 81% of deadly slips, trips, and falls in 2022. Using fall protection can save lives and stop injuries.

Effective Fall Prevention Strategies

Stopping falls starts with good planning. Always check the worksite for dangers before starting. Look for open edges, shaky surfaces, or risky areas. After finding these, take steps to make them safer.

Use personal fall arrest systems (PFAS) when working high up. Make sure workers have harnesses that fit and strong anchor points. Check this gear often for damage. Teach workers how to use PFAS the right way. Studies show trained workers use safety gear better.

By using these tips, you can make the site safer and lower fall risks. Keeping workers safe also helps your projects succeed.

6. Set Up Clear Communication Rules

Good communication keeps construction sites safe. When workers share details well, they can spot dangers and stop accidents. Using the right tools and methods makes the workplace safer and more organized.

Tools to Help Communication on Construction Sites

The right tools help workers stay in touch and aware. Phones, radios, and special apps for construction teams allow quick updates. These tools let workers warn others about dangers fast, lowering injury risks.

Daily safety talks are also very helpful. These meetings let workers talk about risks and review safety steps. They make sure everyone knows their jobs and duties for the day. Open talks during these meetings help workers report problems or ask questions.

Here’s a table showing useful communication practices:

Practice | Description |

|---|---|

Keep Communication Open | Clear talks help workers report dangers quickly and stay safe. |

Hold Daily Safety Meetings | Daily talks inform workers about risks and improve readiness. |

Use Quick Communication Tools | Phones or radios help warn workers about new dangers fast. |

Using these tools improves communication and makes the site safer.

How Communication Helps Stop Accidents

Sharing information helps prevent accidents. When workers talk about dangers, they can avoid them. For example, if someone sees a loose scaffold, they can warn others and fix it before it causes harm.

Clear communication builds trust among workers. When workers feel heard, they report dangers and follow safety rules better. This teamwork creates a safer site and lowers the chance of accidents.

7. Follow Electrical Safety Guidelines

Electrical safety is very important on construction sites. Following rules keeps workers safe and helps work go smoothly. Knowing dangers and using safe practices makes the site safer.

Common Electrical Hazards on Construction Sites

Electrical dangers cause many injuries and deaths in construction. These risks come from bare wires, broken tools, or bad handling of electrical systems. Here are some key facts:

Statistic Description | Value |

|---|---|

4,000 | |

Deaths from electrical injuries yearly in the U.S. | 500-1,000 |

Nonfatal electrical injuries yearly | 30,000 |

Construction worker deaths from electricity yearly | 143 |

Worker deaths from electrocutions (%) | 8.5% |

Electrocutions make up 8.5% of worker deaths. Each year, 143 construction workers die from electrical accidents. Many of these deaths can be avoided by spotting dangers and following safety rules.

Common risks include overloaded circuits, broken wires, and bad grounding. Wet areas also make shocks more likely. Knowing these risks helps you take steps to stay safe.

Best Practices for Electrical Work Safety

Using safe practices lowers risks and follows OSHA rules. Start with an Electrical Safety Program. Update it often to match new rules and teach safe habits to everyone.

Follow these safety tips:

Use Lockout/Tagout Procedures: Turn off power before fixing equipment to avoid accidents.

Provide Comprehensive Training: Teach workers about dangers and safety rules like NFPA 70E.

Inspect Equipment Regularly: Look for damage or wear on tools and wires. Replace broken items fast.

Ensure Proper Installation: Follow NFPA 70 (NEC) and NESC rules for safe wiring and setups.

Wet areas are extra risky. Keep tools dry and use insulated ones to avoid shocks. Always wear the right PPE, like rubber gloves and boots, when near electricity.

By using these tips, you can lower electrical injuries and deaths. Focus on safety to protect workers and finish projects successfully.

8. Use Scaffolding and Ladders Safely

Guidelines for Scaffolding and Ladder Use

Scaffolding and ladders are important tools for construction work. Using them the wrong way can cause bad accidents. Following safety rules helps keep everyone safe. Scaffolding should always be placed on firm, even ground. Never set it on shaky things like barrels or bricks. A trained person must check and guide scaffold setup and removal to ensure safety.

Ladders also need careful use. Check them often for cracks, loose parts, or damage. Replace broken ladders right away. Workers should learn how to use ladders safely. Always secure ladders to stable surfaces to stop them from slipping.

Here are key scaffolding safety rules:

Only trained workers should build scaffolds with supervision.

Add guardrails to scaffolds taller than ten feet.

By following these steps, you can make the site safer and lower fall risks.

Preventing Accidents with Proper Setup

Setting up scaffolding and ladders the right way stops accidents. Pick a flat, stable spot for scaffolding. Avoid uneven ground or loose dirt. Use base plates or mud sills to make scaffolds steadier. For ladders, place them at a safe angle, about 75 degrees, to prevent falls.

Guardrails and toe boards are very important for scaffolding safety. They stop tools and materials from falling and protect workers from slipping. Workers should wear harnesses when working high up. Attach harnesses to strong anchor points for safety.

By focusing on setup and training, you can reduce risks and create a safer worksite.

9. Watch Weather for Construction Safety

Weather can change fast and create dangers for workers. Watching the weather helps you prepare and avoid problems. Planning ahead keeps workers safe and projects on time.

Getting Ready for Bad Weather

Storms, heatwaves, and snow can stop construction work. Being ready for these events lowers risks and keeps everyone safe. Start with a crisis plan. This plan should explain steps to handle emergencies. Work together as a team to make it. Update the plan often to fix new problems.

Check the site for weak spots. Look for areas that need extra support. Secure loose items and cover tools to protect them from wind or rain. For example, tie down materials to stop them from blowing away.

Preparation Step | What It Does |

|---|---|

Crisis Plan | Lists actions and teamwork to prepare for bad weather. |

Risk Check | Finds weak spots and secures tools and structures. |

Tech Tools | Sends alerts to workers about weather and safety steps. |

Changing Work Plans for Weather

Changing work plans for weather keeps workers safe. If bad weather is coming, move tasks indoors or to covered spots. For example, do painting or wiring inside when it rains. Save outdoor jobs for better weather.

Hot and cold weather also need special care. In hot weather, do hard jobs early or late in the day. Give workers shade and water to avoid heat sickness. In cold weather, make sure workers wear warm clothes and take breaks to stay warm.

10. Create and Practice an Emergency Plan

Emergencies can happen anytime on construction sites. Being ready can save lives and prevent injuries. A good safety plan helps everyone know what to do in emergencies. This preparation keeps workers safe and projects moving forward.

Important Parts of an Emergency Plan

A strong emergency plan has several key parts. First, find risks specific to your site. These might include fires, spills, or bad weather. After identifying risks, make clear steps for each situation. For example, show evacuation routes and pick safe meeting spots.

Next, assign roles to workers. Choose leaders to guide others during emergencies. These leaders should help workers follow the plan and stay safe. Give them tools like radios or whistles to communicate clearly.

Train Workers for Emergencies

Training helps workers handle emergencies better. Teach them how to respond to fires, injuries, or other problems. Use drills to practice evacuations and first aid steps. Repeating drills helps workers stay calm and act fast in real emergencies.

Focus on communication during training. Show workers how to report problems and follow leaders’ instructions. Clear communication stops panic and keeps everyone safe.

11. Limit Access to Authorized Personnel Only

Why Unauthorized Access is Dangerous

Letting untrained people into construction sites is very risky. These areas have heavy machines, unsafe surfaces, and harmful materials. Without training, it’s hard to stay safe in such places.

Unauthorized visitors can cause accidents or damage property. For instance, someone might touch equipment or enter dangerous zones without knowing the rules. In cities, pedestrians near construction sites can accidentally wander into restricted areas. This puts both workers and visitors in danger.

How to Control Site Access

Use barriers, technology, and rules to control access. Start by putting up fences or walls around the site. Locked gates or guards can add extra safety.

Technology helps manage who enters. Use badges, keycards, or fingerprint scanners for workers. Cameras can record activity and scare off trespassers. For risky areas, alarms or motion sensors can catch unauthorized movement.

Make clear rules about who can enter. Teach workers to follow these rules and report problems. Assign guards or supervisors to check access. Update your rules often to handle new issues.

By using these methods, you can protect workers, avoid risks, and keep the site running smoothly.

12. Conduct Regular Safety Inspections

Why Routine Inspections Are Important

Regular safety checks make construction sites safer and prevent accidents. These inspections help find dangers before they cause harm. For instance, checking scaffolding or electrical systems can stop injuries and save lives.

Data shows inspections work. In New York City, Local Law 196 cut deadly construction accidents by 236% from 2022 to 2023. In Los Angeles, a safety law lowered construction deaths by 15% between 2020 and 2023. These numbers prove how important regular inspections are.

Using checklists makes inspections easier and more effective. The Chandos team used checklists to spot problems and fix them fast. This method ensures thorough checks and quick solutions. Switching to digital tools like BIM 360 can also help. It cuts reporting time by 30% and gives instant access to safety info.

Checklist for Complete Safety Inspections

A good safety checklist helps keep your site safe. Use it to check that workers follow rules and equipment works properly.

Key Things to Check:

Make sure the site is free of dangers.

All workers must wear the right PPE.

Machines and electrical tools should work well.

Entry rules and safety steps must be clear.

Emergency plans should be ready and known by everyone.

Why Checklists Help:

Keep workers safe by spotting risks early.

Lower safety problems and avoid expensive accidents.

Show your commitment to safety and build trust.

Using a checklist ensures your site meets safety rules. This careful approach protects workers and keeps projects on schedule.

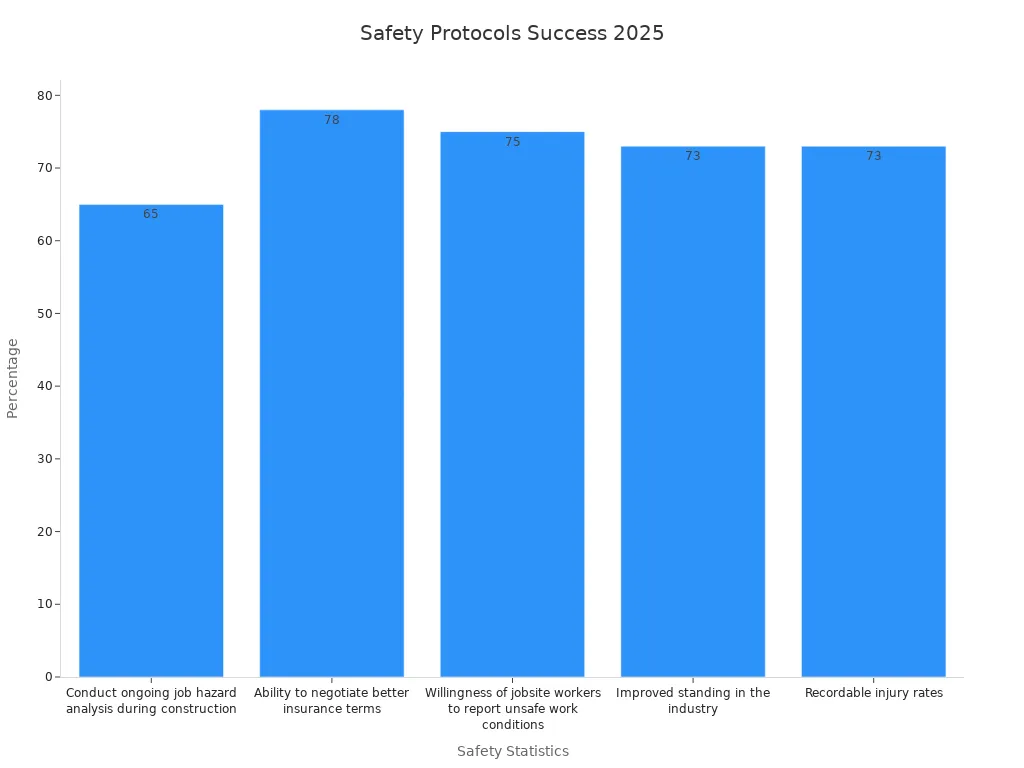

A strong focus on safety helps everyone. Workers feel safer, and projects go better. Studies show 75% of workers report dangers when safety rules exist. Companies that care about safety improve their reputation by 73%.

Statistic | Percentage |

|---|---|

Check for hazards during construction | 65% |

Get better insurance deals | 78% |

Workers reporting unsafe conditions | 75% |

Better industry reputation | 73% |

Fewer injuries | 73% |

Learning and following safety rules keep you ready for new challenges. By sticking to these rules, you protect workers and help projects succeed.

FAQ

What is the most important safety rule on a construction site?

Always wear the right PPE to stay safe. It protects you from falling objects, sharp tools, and harmful materials. PPE is your best defense against common site dangers.

How often should safety training be conducted?

Attend safety training at least once every month. These sessions teach new safety tips and refresh old ones. Regular training lowers accidents and builds safer habits.

Why is keeping the worksite clean so important?

A clean site stops trips, falls, and other accidents. It helps workers focus and move safely. Cleaning also reduces risks from sawdust or spilled liquids.

What should you do if you notice a safety hazard?

Tell your supervisor or safety officer right away. Acting fast can stop accidents and keep everyone safe. Never ignore even small hazards.

How can you prepare for extreme weather on a construction site?

Check weather reports daily and change plans if needed. Secure loose items and give workers proper gear for heat, cold, or rain. A crisis plan helps everyone know what to do in bad weather.

Start writing here...