Extensive Compatibility

Allow all ISOBUS-compatible implements to be connected to the FJD guidance and steering systems, enabling equipment from different brands to work together.

Precise Operation

Assist with application rate adjustment, performance monitoring, and real-time feedback, helping farmers to optimize their operations and reduce investments

Simplified Workflow

Provide a unified and user-friendly FJD interface to reduce the need for multiple monitors and control systems, making it easier for operators to manage different implements and streamline their workflow.

Easy Data Management & Transfer

Collect and transfer operational data to smart management platforms, like FMS, to create prescription maps and plan future job assignments.

Wiązka przewodów ISOBUS

Sugerowana cena detaliczna: 749 €

TC-SC/TC-GEO/AUX

Sugerowana cena detaliczna: 599 €

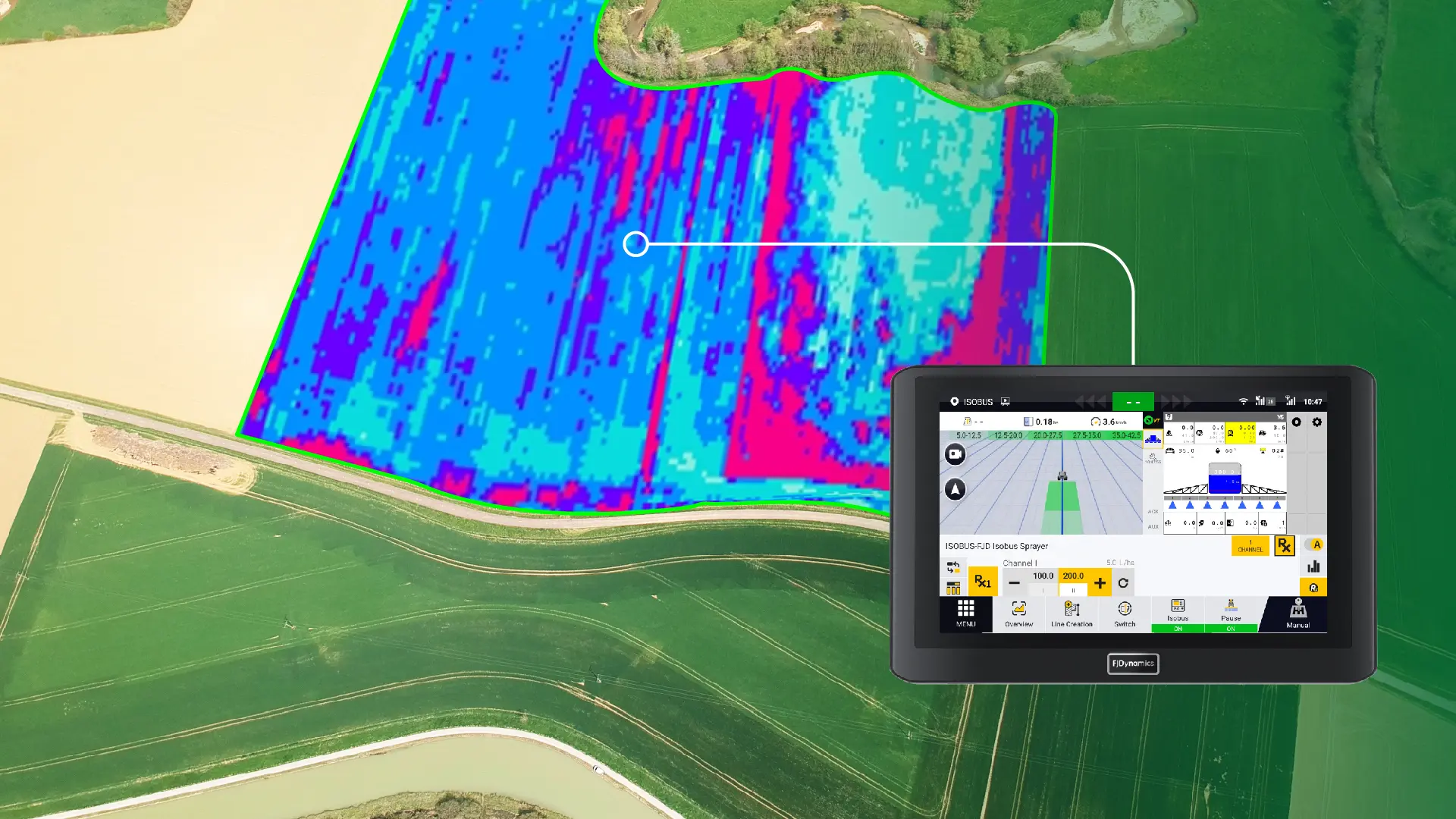

Unified Connectivity, Simplified Farming

That's just the beginning of how the FJD ISOBUS technology changes the way you manage a fleet of implements from different manufacturers.

With variable rate application and automatic section control, the FJD ISOBUS technology makes it easier for you to manage multiple implements at the same time, bringing more efficiency to your farming operations.

Virtual Terminal: Effortless Control, Seamless Integration

Virtual Terminal: Effortless Control, Seamless Integration

Task Controller: Automate Tasks, Boost Efficiency

Task Controller Basic (TC-BAS)

Task Controller Section Control (TC-SC)

TC-GEO – Task Controller Geo-Based (Variables)

AUX-N: Auxiliary Control, Reduced Complexity

AUX-N: Auxiliary Control, Reduced Complexity

Explore ISOBUS-Compatible Applications

AEF Certification of FJDynamics Products

AEF Certification of FJDynamics Products

Cable Specs

ISOBUS

-

Communication Type

IBBC, In-cab

-

Transfer Protocol CAN

-

Operating Temperature -30℃ to 70℃

-

Operating Humidity 5% - 95%

-

Storage Temperature -45℃ to 85℃

-

IP Rating IP67

-

Data Transfer Rate in CAN Bus 250Kbps